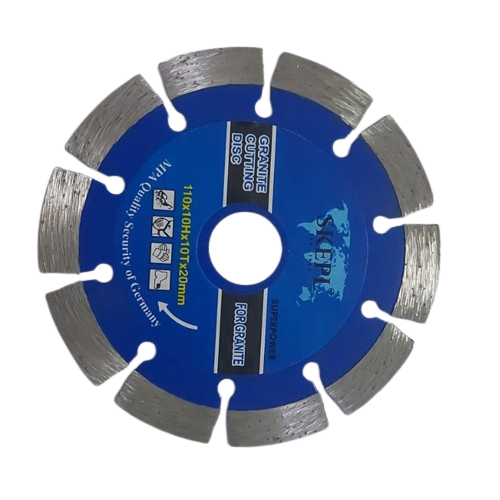

Granite Cutting Blades

Price 98 INR/ Piece

Granite Cutting Blades Specification

- Cutting Capacity

- Heavy Duty (Granite, Stone)

- Features

- Long Life, Fine Finish, High Stability, Improved Productivity

- Shape

- Circular

- Tool Type

- Cutting Blade

- Cutter Type

- Diamond Segmented Blade

- Cutting Force

- High

- Material

- Steel Core with Diamond Segments

- Operate Method

- Manual & Machine Operated

- Cutting Speed

- Fast

- Machine Type

- Granite Cutting Machine, Table Saw

- Operation Type

- Wet & Dry

- Coating Type

- Diamond Grit

- Hardness

- Super Hard (fit for Granite)

- Coating

- Electroplated Diamond

- Cutting Accuracy

- High Precision

- Diameter

- 350 mm

- Processing Type

- Cutting

- Service Life

- Extended (Up to 3x regular blades)

- Applications

- Granite, Marble, Hard Stone Cutting

- Segment Width

- 3.2 mm

- Center Hole Diameter

- 50 mm

- Usage

- Industrial, Professional

- Cooling Requirement

- Water-cooled Recommended

- Noise Level

- Low

- Segment Height

- 10 mm

Granite Cutting Blades Trade Information

- Minimum Order Quantity

- 800 Pieces

- Supply Ability

- 10000 Pieces Per Day

- Delivery Time

- 1 Week

About Granite Cutting Blades

Granite Cutting Blades: Application & Usage

These granite cutting blades excel in industrial and professional settings-ideal for processing granite, marble, and other hard stones. Used by manufacturers, suppliers, traders, exporters, and importers across India, they are suited for granite cutting machines and table saws. Simply install in your machine or operate manually for wet or dry cutting, ensuring high precision and optimal productivity at every step.

Granite Cutting Blades: Supply, Certifications & Packaging

We charge ahead with reliable supply of our granite cutting blades, supported by robust certifications that guarantee performance and safety. Each blade is securely packaged for protection during transport, ensuring quality upon delivery. With strong supply chains and efficient packaging, you receive dependable, certified blades ready for immediate use in demanding industrial environments.

FAQ's of Granite Cutting Blades:

Q: How should the Granite Cutting Blades be used for optimal performance?

A: For best results, operate the blades on granite cutting machines or table saws, with water cooling recommended to enhance longevity and cutting precision. You may use them for both wet and dry cutting applications.Q: What materials can be cut with these blades?

A: These blades are engineered for heavy-duty cutting of granite, marble, and other hard stones, delivering high accuracy and fine finishes even on the toughest surfaces.Q: Where are the Granite Cutting Blades typically applied?

A: These blades are used in industrial workshops, manufacturing units, stone processing factories, and professional construction sites throughout India and globally.Q: When should you choose these blades over regular ones?

A: Select these blades when your projects demand extended service life, high cutting speed, and superior precision, especially for heavy-duty and continuous stone processing tasks.Q: What is the supply process for Granite Cutting Blades?

A: Blades are available from exporters, importers, manufacturers, suppliers, and traders, backed by certifications and securely packaged for reliable delivery to customers.Q: What are the benefits of using these blades for industrial applications?

A: Users gain improved productivity, reduced noise levels, fast and accurate cuts, and up to three times the longevity compared to standard cutting blades.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cutting Wheel Category

SKEPL 4-INCH Cutting Wheel DOUBLE NET

Price 9.00 INR / Piece

Minimum Order Quantity : 800 Pieces

Operate Method : USE SAFTY GUARD

Processing Type : 80M/S

Material : PREMIUM ALUMINIUM OXIDE GRAINS

Maximum Torque : 15200 gfmm

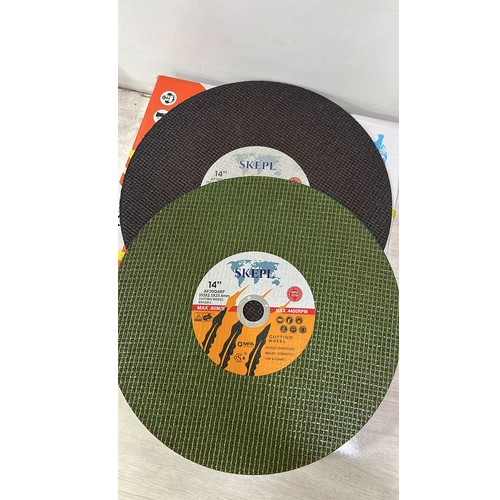

SKEPL 14-INCH CUTTING WHEEL

Price 100.00 INR / Piece

Minimum Order Quantity : 25 Pieces

Operate Method : USE SAFTY GUARD

Processing Type : 80M/S

Material : High Speed Steel

Maximum Torque : 15200 Ibfin

14-INCH SKEPL CUTTING WHEEL DOUBLE NET

Price 110.00 INR / Piece

Minimum Order Quantity : 25 Pieces, Piece

Operate Method : Manual

Processing Type : 80M/S

Material : High Speed Steel

Maximum Torque : 15200 gfm

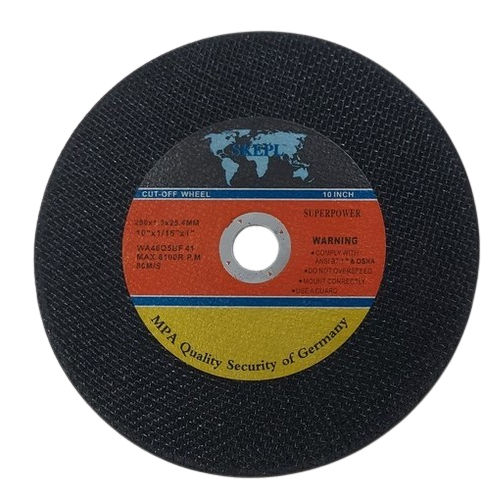

10Inch SKEPL Cut-off Wheel

Price 65.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : GRINDER

Processing Type : HOT PRESS

Material : Carbide, High Speed Steel, Tungsten Cobalt Alloy, Steel, Hard Alloy, Tungsten Carbide, Stainless Steel, Alumina, Metal, Carbon Steel, Chrome Vanadium, Cobalt Alloy

Maximum Torque : 0.001 Ibsin

|

SHREE KAMADGIRI ENTERPRISES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry